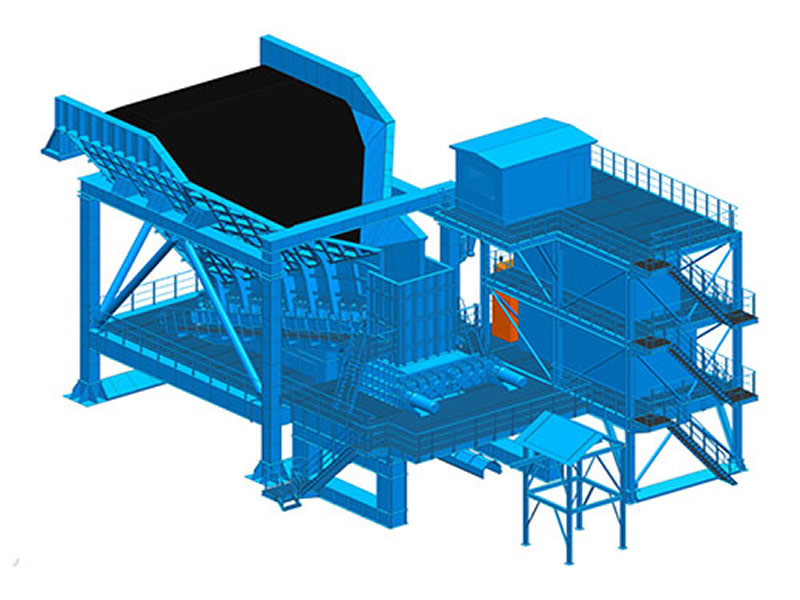

Double- roller semi-mobile crushing station, suitable for the technology of truck-semi-mobile crushing station-belt conveyor, is applicable to the crushing of the material with medium hardness or viscous and soft material. Modularized design of the crushing station brings convenience for its relocation; it can be transported by crawler transporter or dragged by large spreader.

Specification:

Rated capacity:2000t/h~12000t/h

Receiving grain size:0~2000mm

Discharging grain size:0~450mm

Application

Double-roller crushing station is applicable to primary crushing of gross coal or striping material in large open-pit mine with output above ten million tons and is suitable for the technology of single bucket excavator-transporting truck-semi-mobile crushing station-belt conveyor. Utilizing the flexibility of the truck to shorten transporting distance and exploiting the advantages of its long distance transport, high productivity, low cost and maintenance and high reliability. Moreover, it can be relocated regularly as per mining demand.

Features

01.Semi-mobile crushing station consists of modules of hopper and crusher and control tower. All modules can be relocated by crawler transporter.

02.Screening crusher with low rotatary speed and high torque, utilizing the inner layer and crack of the material to shear and crush material. It can be easily cleaned and conveniently maintained.

03.Sealed transfer point, using anti-overflow plate to seal up the belt and discharging chute so as to reduce dust pollution.

Parameters

| Rated capacity (t/h) | Receiving grain size(mm) | Discharging grain size(mm) | Total power(kW) | QTY. of Unloading platform | Volume of hopper(m3) | Model of crusher | Motor power(kW) | Center distance of feeder (mm) |

| 9000 | 0-2000 | 0-400 | 2710 | 2 | 500 | 16/350CCTD | 2×630 | 14600 |

| 7000 | 0-2000 | 0-400 | 2100 | 2 | 300 | 13/300CCTD | 2×355 | 14800 |

| 4500 | 0-2000 | 0-400 | 1670 | 2 | 220 | 11/300CCTD | 2×355 | 14700 |

| 3000 | 0-1500 | 0-300 | 1165 | 2 | 220 | 11/220CCTD | 355 | 14700 |

Address

Navigation

Links

QR Code